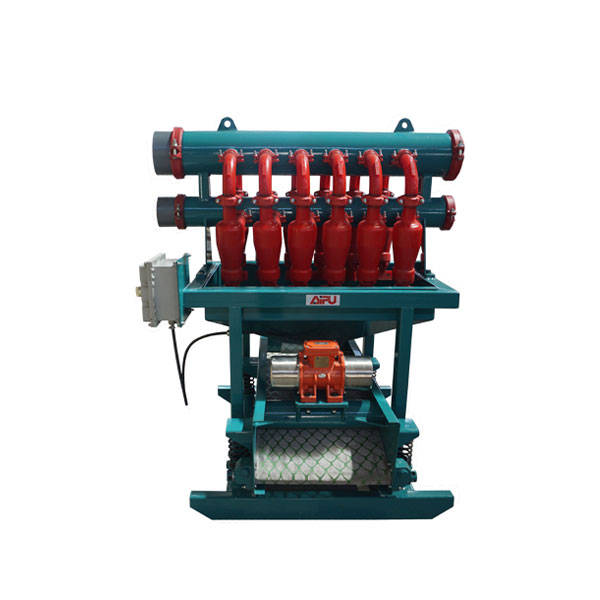

The Vertical centrifugal degasser unit provides an innovative and space-saving solution to degassing problems. The centrifugal degasser use a centrifugal-force system rather than conventional vacuum or impact systems. Vertical degasser exert centrifugal force to the mud, multiplying the force acting on the gas bubbles to increase buoyancy and release. The increase in buoyancy accelerates the bubble-rise velocity. As the bubbles rise toward the surface, they escape the mud and are further broken down by flow turbulence. The freed gas and the gas-free mud are then separately discharged as desired.

Additional benefits of using a vertical centrifugal degasser:

Reduced maintenance costs

Improved drilling efficiency

Reduced risk of lost circulation

The Vertical centrifugal degasser unit provides an innovative and space-saving solution to degassing problems.

Conventional vacuum or impact degassers can be large and bulky, and they can require a lot of maintenance. The vertical centrifugal degasser unit is a more compact and efficient alternative to these conventional degassers. It is also easier to maintain.

The centrifugal degasser uses a centrifugal-force system rather than conventional vacuum or impact systems.

Centrifugal degassers use a centrifugal-force system to remove gas bubbles from drilling mud. This system is more efficient than vacuum or impact systems, and it can remove a wider range of gas bubble sizes.

Vertical degassers exert centrifugal force to the mud, multiplying the force acting on the gas bubbles to increase buoyancy and release.

The vertical centrifugal degasser unit exerts centrifugal force to the mud, which multiplies the force acting on the gas bubbles. This increased force helps to increase the buoyancy of the gas bubbles and release them from the mud.

The increase in buoyancy accelerates the bubble-rise velocity.

The increased buoyancy of the gas bubbles causes them to rise more quickly. This accelerated bubble-rise velocity helps to remove the gas bubbles from the mud more quickly.